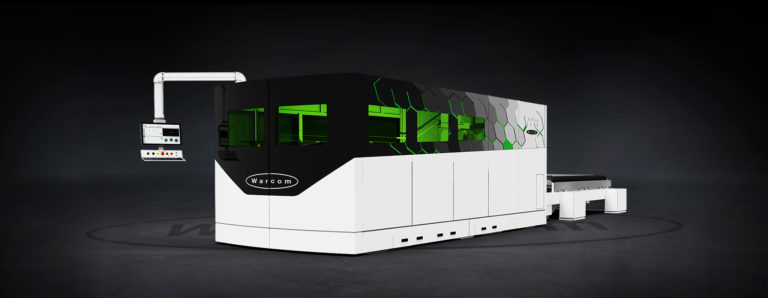

Gamme de machine laser italienne

Machine laser fibre jusqu'à 12kW !

La marque Warcom commercialise une gamme de machine laser fibre performantes et de haute-précision. En effet, ces machines de découpe laser sont équipées de sources laser fibre IPG ou Trumpf TruDisk disponibles de 1 à 12 kW.

En effet, cette marque historique italienne profite d’une expérience de plus de 40 ans dans le développement de solutions de pointe sur le marché de la machines-outils, Warcom propose une gamme complète de machine laser fibre pour les applications sur tôles et tubes, mais aussi une gamme de plasma et presses plieuses hydrauliques et électriques.

Grâce à la technologie fibre de dernière génération, la machine permet de réaliser des économies d’énergie très intéressantes, aussi bien au niveau du gaz, qu’au niveau de l’électricité. A titre de comparaison, par rapport au laser CO2, le laser fibre garantit une réduction de la consommation d’énergie de plus de 70 % et une réduction des coûts d’exploitation de plus de 50 %, ainsi que des coûts d’entretien de routine extrêmement faibles grâce à un ensemble de pièces détachées qui ne sont pas nécessaires sur les machines de découpe laser fibre.

Découvrez dans notre vidéo en bas de page la vidéo de présentation des machine laser fibre Warcom en pleine production. Vous constaterez clairement des machines laser alliant vitesse de coupe et précision !

Une gamme de machines en réponse aux attentes des industriels

Warcom propose une gamme complète de machines laser fibre de haute qualité, adaptées à diverses applications. Leurs lasers fibre pour le découpage sur tôles offrent une précision et une vitesse exceptionnelles, permettant d’obtenir des résultats sans bavure, même dans les matériaux les plus exigeants. Pour les travaux de découpe sur tubes, Warcom propose des machines spécialisées qui garantissent des résultats précis et efficaces, quel que soit le diamètre du tube. Que vous soyez dans l’industrie automobile, aérospatiale, métallurgique ou toute autre industrie nécessitant une découpe laser précise, Warcom a la machine laser fibre adaptée à vos besoins.

Des modèles qui ont pour point commun, l’utilisation des meilleurs composants sur le marché : Commande numérique (CNC) et variateurs d’axes Beckoff, source laser à fibre IPG ou Trumpf TruDisk, règles optiques Renishaw ou encore des bâtis en béton polymère de la marque Rampf.

Faites confiance à la technologie de pointe de Warcom pour optimiser votre productivité et atteindre de nouveaux sommets en termes de qualité de découpe.

Les avantages de la tête de coupe Precitec ProCutter 2.0

Depuis le début, les machines laser Warcom sont équipées d’une tête de coupe de la marque référence sur le marché : Precitec. Avec les avancées technologiques, les machines laser à fibre sont désormais équipées des nouvelles têtes de coupe ProCutter 2.0, capable d’utiliser le faisceau des machines les plus puissantes. Cette tête est le fruit de nombreuses années d’investissement en R&D dans l’industrie laser. L’innovation est depuis toujours au coeur de la stratégie de la marque !

Voici les avantages de cette tête de coupe laser Precitec :

- Vitesses de coupe élevées grâce à un faible poids;

- Usinage stable de matériaux épais;

- Entretien facile et rapide;

- Rapidité de perçage améliorée;

- Possibilité de découpe laser jusqu’à 60kW;

- Centrage automatique de la buse;

Des zones de travail personnalisées pour votre machine laser à fibre

Outre l’innovation, la marque Warcom revendique une flexibilité et une adaptation permanente aux besoins de ses clients industriels. Face à la concurrence, nous savons qu’il est primordial pour nos clients de tirer leur épingle du jeu pour l’usinage de leurs pièces métalliques. Pour ce faire, il peut être nécessaire pour eux d’agrandir ou rétrécir la zone de travail de leur machine laser à fibre.

Pour répondre à ces attentes, sachez que nous sommes désormais en mesure de proposer des tables de coupe pouvant aller jusqu’à 12 mètres de longueur et 3 mètres de largeur. Une conception idéale pour les industriels qui ont des problématiques spécifiques au niveau de la taille des pièces usinées.

Tous les autres avantages du laser fibre Warcom

Comme vous l’aurez compris, notre partenariat avec Warcom prend tout son sens pour SERVILASE car c’est une entreprise qui partage nos valeurs. Elle a une réelle volonté de satisfaire les clients dans leur utilisation laser au quotidien.

En résumé, voici pourquoi nos clients choisissent la marque Warcom pour leur laser fibre :

- Performances élevées : Accélération maximale de 2G et vitesse maximale de 210 m/min sur les axes interpolés pour une productivité accrue.

- Précision incomparable : Tête de coupe à entraînement direct et système de contrôle de la hauteur automatique pour des résultats d’une précision exceptionnelle.

- Polyvalence remarquable : Large choix de sources laser et de configurations pour répondre aux exigences spécifiques de chaque application.

- Efficacité énergétique optimale : Faible consommation de gaz et d’électricité pour un impact environnemental réduit et des coûts d’exploitation minimisés.

- Facilité d’utilisation : Interface intuitive et conviviale pour une prise en main rapide et une utilisation simple.

- Fiabilité et robustesse : Composants de haute qualité et construction robuste pour une durabilité accrue.

Laser fibre ou CO2 ?

Vous hésitez entre l’achat d’une machine fibre ou CO2 d’occasion pour votre entreprise ?

Nous avons rédigé un article sur notre blog afin de vous éclairer sur la façon de choisir votre machine de découpe laser. Si vous souhaitez voir une machine fibre Warcom en fonctionnement, n’hésitez pas à nous contacter. En effet, plusieurs machines produisent déjà en France.

Enfin, afin de répondre aux demandes de tous nos clients lorsque le budget peut être réduit, nous avons lancé notre service de machine découpe laser d’occasion. Ces machines sont idéales pour démarrer une activité de découpe.