Storage systems are an efficient solution for companies that handle large quantities of sheet metal or long products made of steel, stainless steel or aluminum. They offer many advantages such as savings in logistical time, organization, space and security.

In this article, we will give you an overview of the top 3 reasons why our customers invest in sheet metal storage systems, whether they are towers or racks, automated or not.

1. Faster sheet metal storage than ever before

The main advantage of investing in storage racks for sheet metal is that they allow faster and more secure storage. Racks or storage towers for sheet metal are designed to accommodate sheet metal in a way that it is better organized and can be quickly moved back and forth between production and storage. This allows our customers to improve material flow and thus save time and space in their facilities. In addition, the storage racks protect the materials from external conditions and weathering, thus providing protection against corrosion.

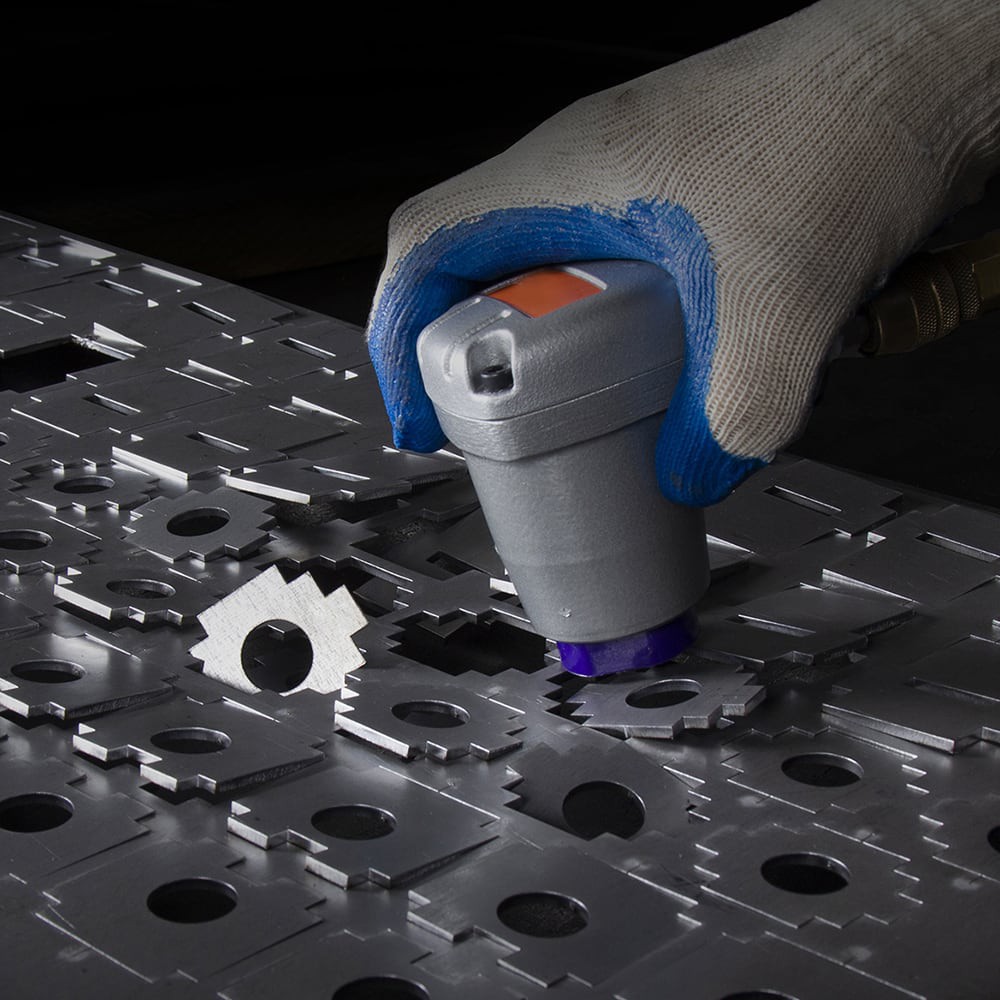

2. Less manual handling of sheets for better safety

Sheet metal storage systems reduce manual handling. This greatly reduces the risk of damage to the sheets, the risk of injury to the operators and improves overall productivity. In addition, it is also possible to automate these storages with fully automated racks. This is the specialty of our German partner Remmert. On the other hand, we can consider standard or custom configurations. Each one can be equipped with additional security systems.

3. More flexibility in production

Finally, storage racks offer companies greater flexibility. For example, our partner Remmert offers the creation of racks that are 100% customized to the size and dimensions of each workshop. The racks can be adapted to both small and large storage spaces, allowing companies to optimize space and use their storage space more efficiently.

Lhe intelligent control system SMART Control is the heart of the Remmert goods flow solution. It consists of two modules. On the one hand, the Control module, which enables the control of the system and is responsible for visualization, process control, diagnosis and troubleshooting. On the other hand, the WMS BASIC module which represents the inventory management system with simple and intuitive inventory management. These two modules form a powerful control system with an intuitive graphical user interface.

In conclusion, investing in sheet metal storage racks offers many benefits to businesses. It allows for more efficient storage, reduced costs, less manual handling, increased security and more flexibility through customization and automation. As you can see, sheet metal racks are an excellent solution for companies that handle large quantities of sheet metal.